“It took me a few seconds to draw it, but it took me 34 years to learn how to draw it in a few seconds“

- Paula Scher

How can we help you?

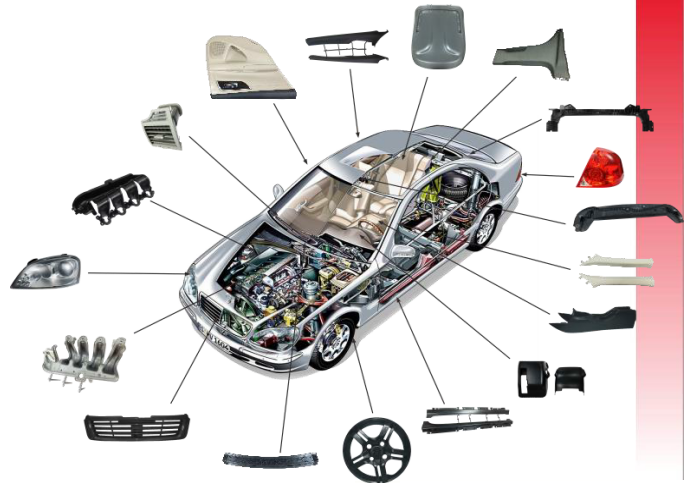

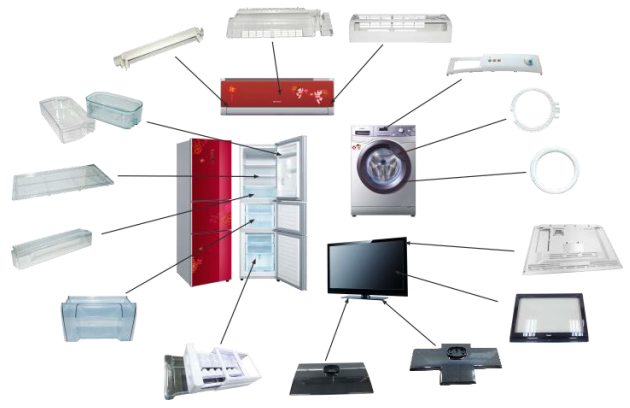

Model analysis for tool feasibility

Development of tool concepts

Support / recommendation when designing the injection point

Short delivery times of the designs with any number of tool designs

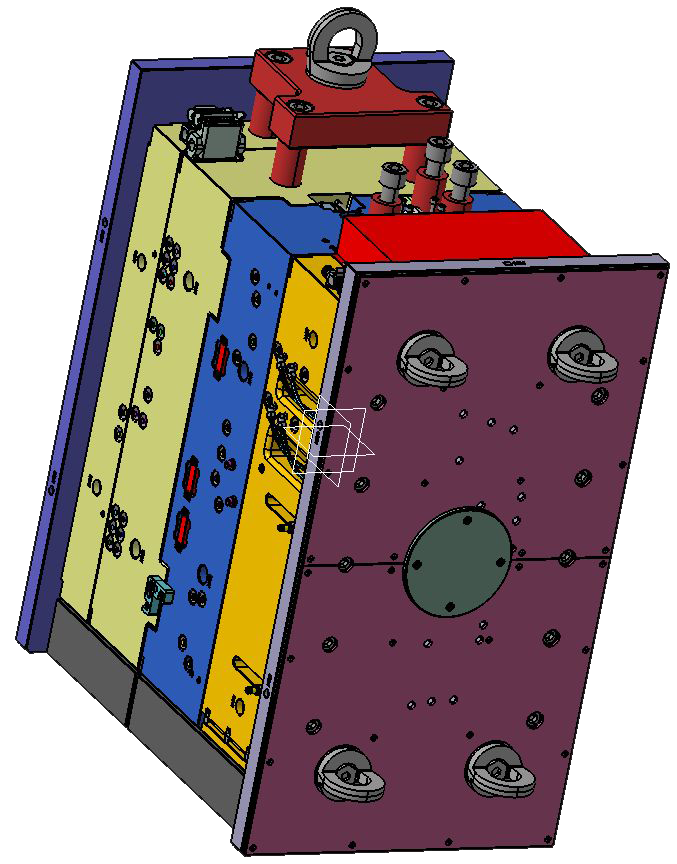

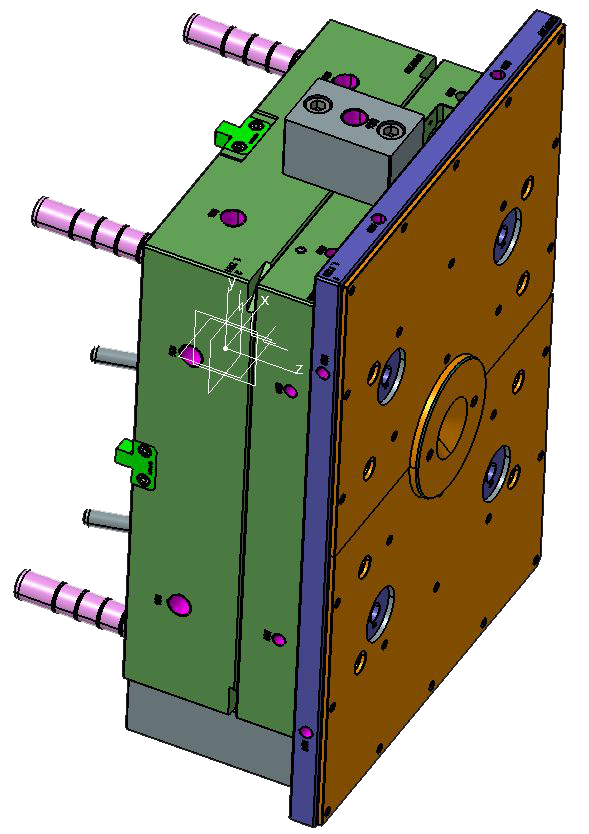

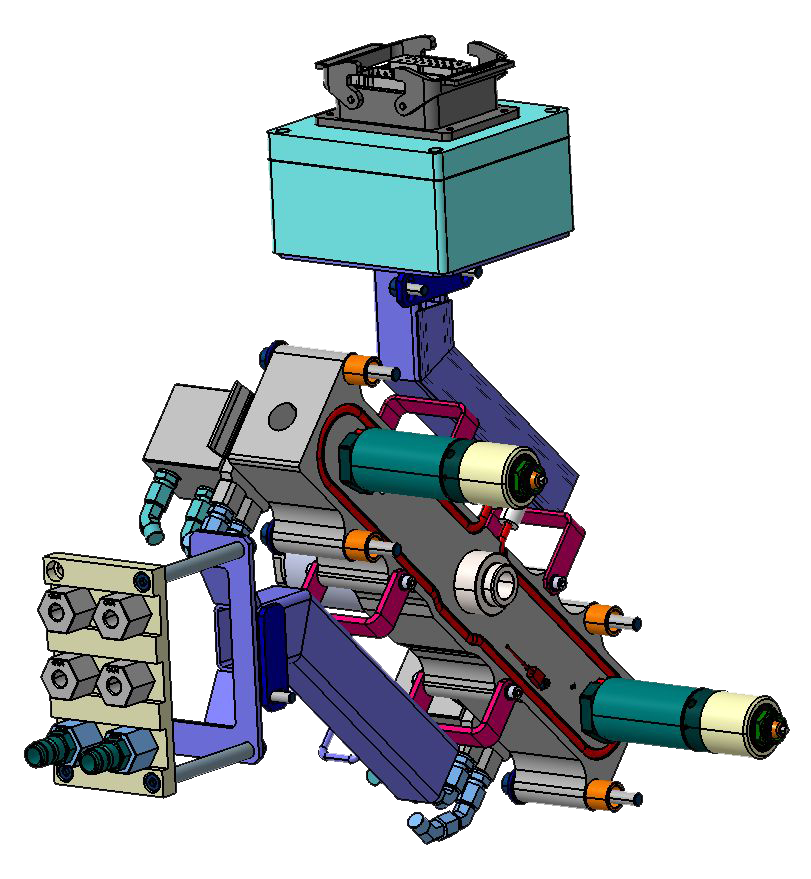

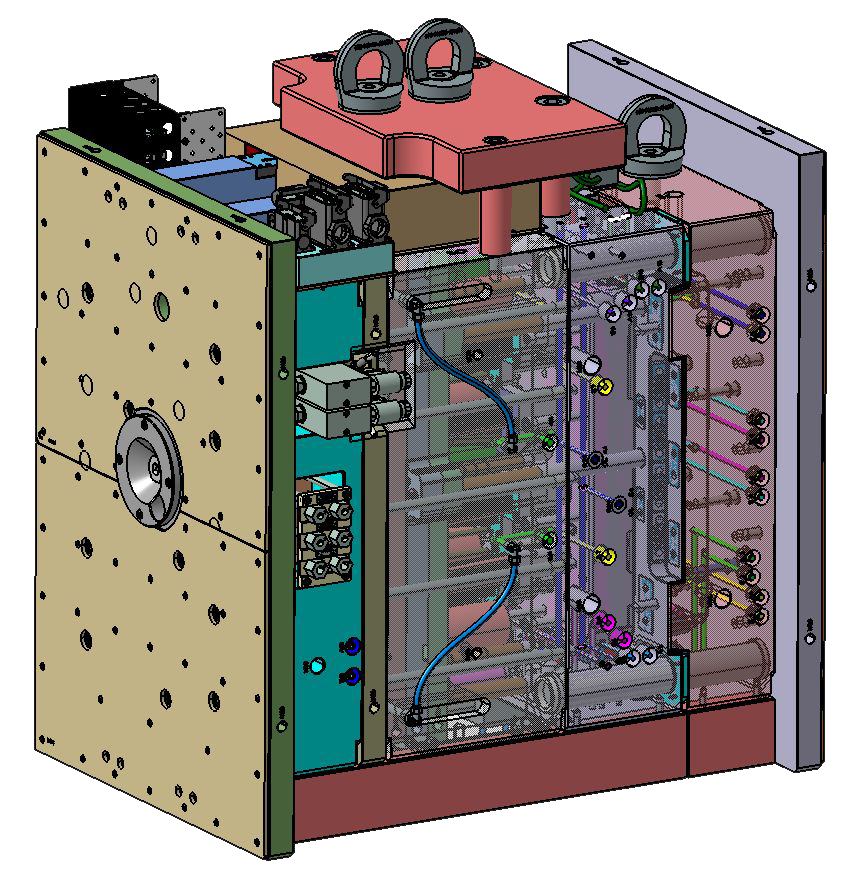

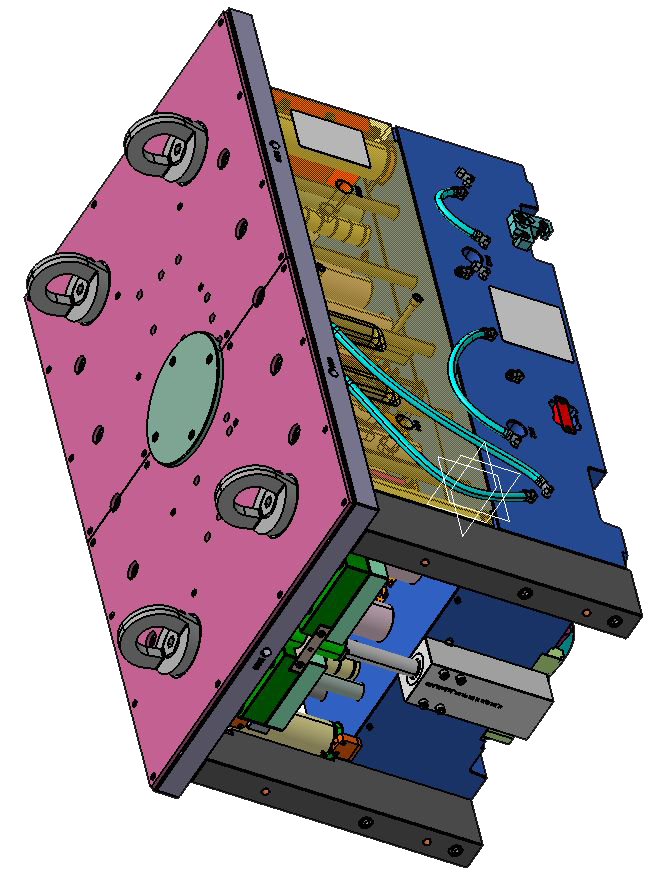

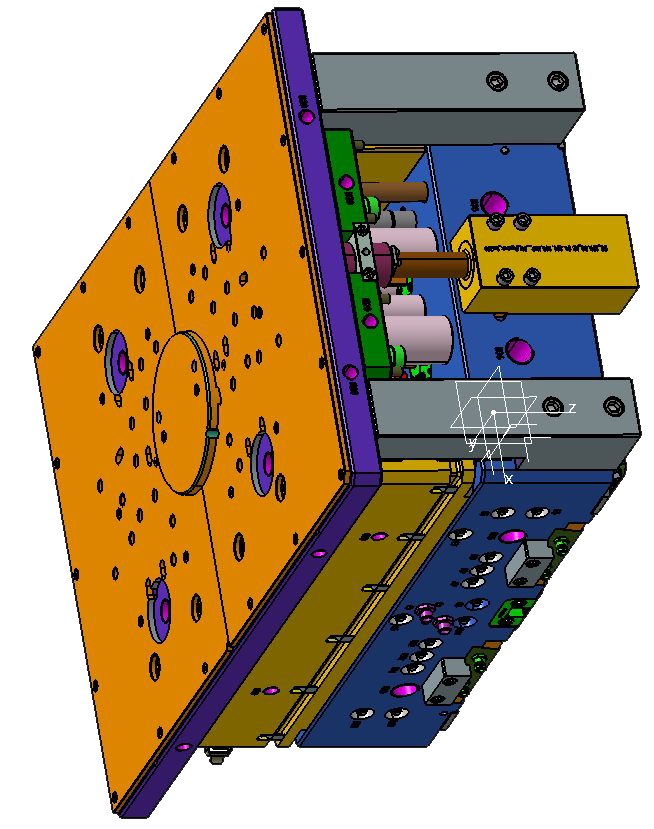

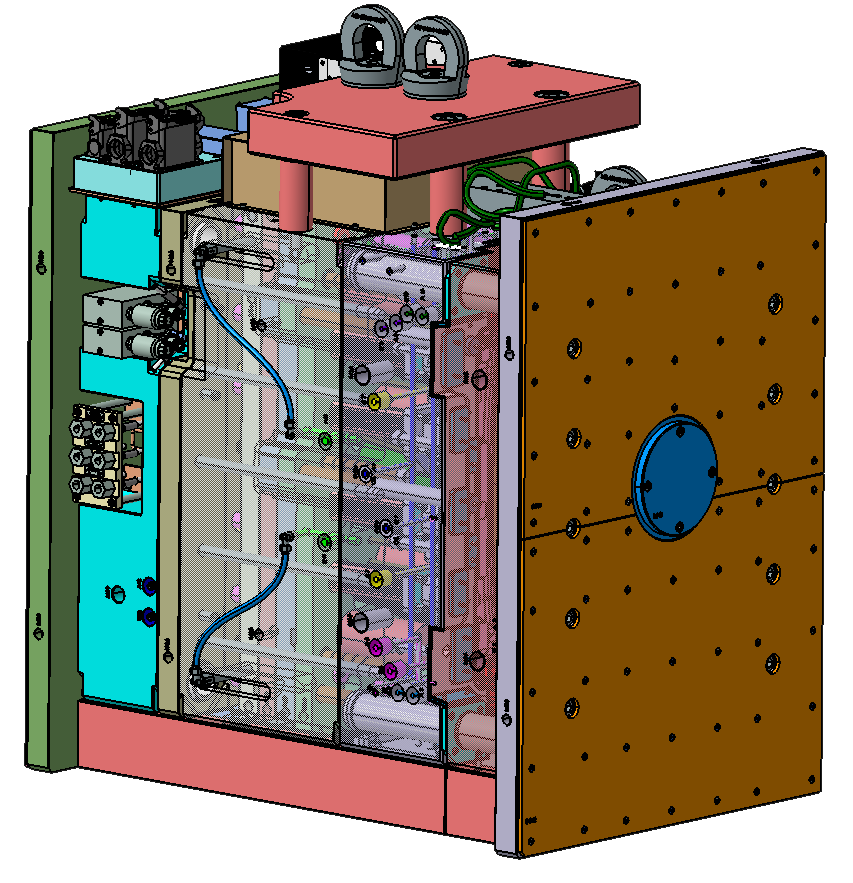

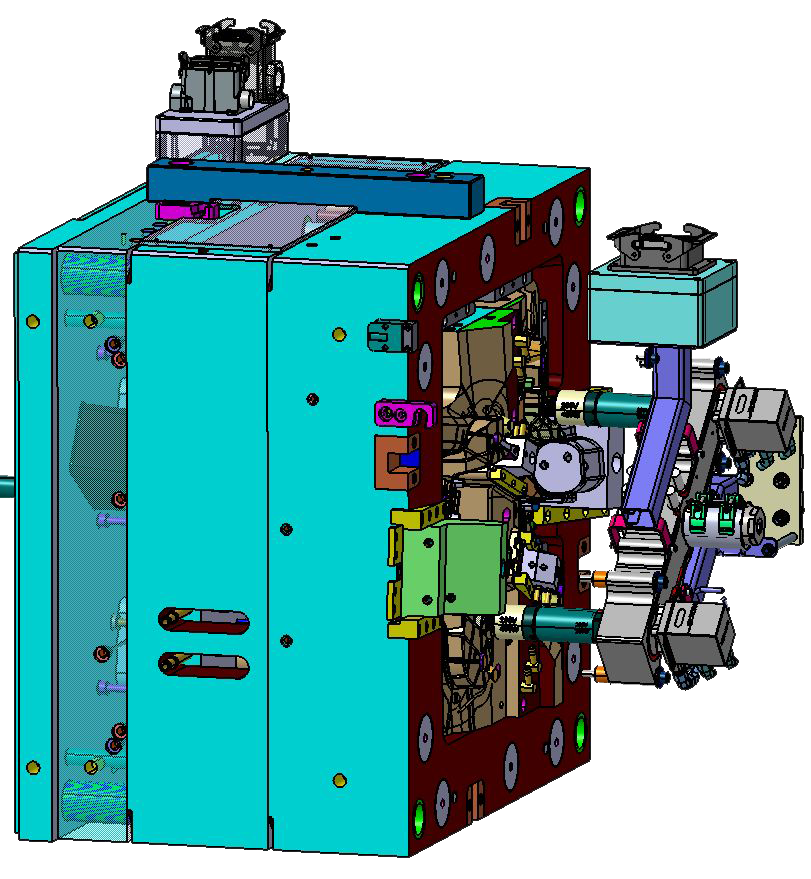

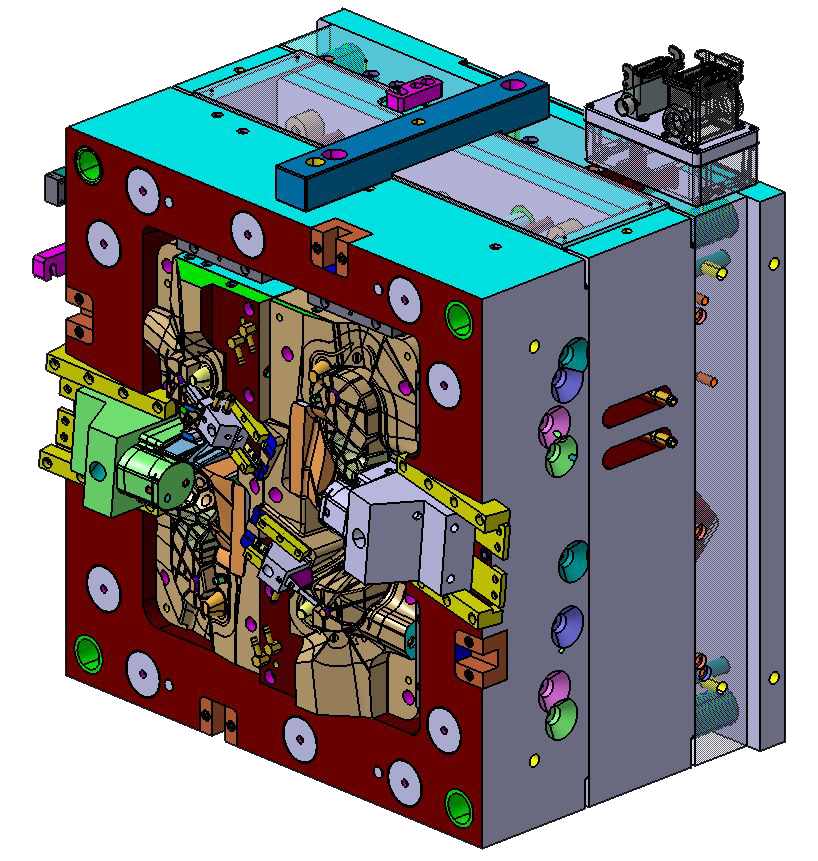

3D constructions of injection molds:

Model analysis

Vor der Konstruktion des Werkzeuges steht die Modelanalyse. Das 3D-Modell bzw. der Prototyp wird auf werkzeugtechnische Machbarkeit geprüft. Sollte bei der Prüfung festgestellt werden, dass das Model nicht werkzeuggerecht ausgelegt ist, machen wir Ihnen einen Verbesserungsvorschlag.

3D construction design

When designing the injection molding tool, we use as many standard parts as possible (standardized basic elements in tool making). This ensures low costs and high process reliability through long-proven components of the tool. In addition, the tool can be repaired quickly and inexpensively in the event of later repairs.

Lay out of injection points

Um in der Fertigung mit Spritzgusswerkzeugen das bestmögliche Teil zu erzeugen, ist die optimale Auslegung der Anspritzstellen Voraussetzung. Sie gewährleisten ein balanciertes Fließverhalten des Polymers, bei dem die äußeren Punkte zur gleichen Zeit und mit dem gleichen Druck befüllt werden können und die volumetrische Schwingung dem Idealwert nahe kommt. Gerne arbeiten wir Ihnen dazu Empfehlungen aus.